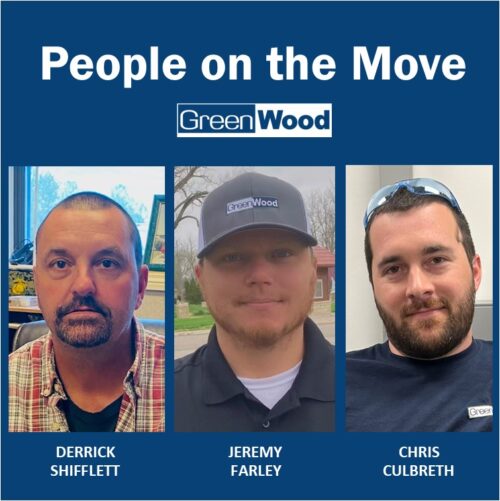

We are pleased to announce several individuals at GreenWood who have been appointed to site leadership roles at projects across the U.S. Derrick Shifflett is now Site Manager at our project in Elkton, Virginia. Jeremy Farley has re-located to Emporia, Kansas to lead our project there as Site Leader. In the Greenville, SC area (Piedmont), Chris Culbreth has been named Site Leader to lead the maintenance team at this project. Congratulations to these new leaders at Team GreenWood!

Tag: best maintenance practices

Continuous Improvement Requires a Proactive Maintenance Approach

Written on . Posted in Press Releases.

Maintenance should be a constantly improving activity, which enhances the quality of service, streamlines processes and optimizes operating costs. A continuous improvement environment includes the necessary elements to assess situations and determine improvement opportunities through the application of the following:

• Defining maintenance processes and how critical equipment will be maintained with a focus on failure modes for critical components

– Every maintenance task needs to be directly aimed at creating the best “value” from the assets.

• Assessing the available resources and required tools necessary for proactive maintenance jobs

– Work needs to be executed efficiently and effectively which requires a meticulous work management process to prevent wasteful reworks.

• Establishment of overall objectives with KPI’s for progress checkpoints

– The development and implementation of a ‘balanced scorecard’ of Key Performance Indicators (KPIs) and the support and communication from management are the keys to delivering improvement.

• Integrating the process into a maintenance management system to capture all data points, track activity, and provide reporting analysis

– All data points related to equipment, critical assets, work orders, backlog, labor/man hours, costs, PM schedules, spare parts and more should be monitored and measured to identify where improvements have been made and where they are needed.

Expect the Unexpected

Planning and scheduling is an important element that contributes to maintenance productivity and continuous improvement. However, unexpected failures will occur and disrupt the completion of planned and scheduled work. With this in mind, increased planned work that is focused on eliminating defects (the causes of unplanned work) will result in efficiency gains.

It Continues – as it Should

Ongoing improvement means it continues without ending. The maintenance process requires regular reviews, modifications and adjustments when things change. Taking this approach to continuous improvement will increase uptime and throughput, reduce safety incidents, increase equipment reliability and planned maintenance work resulting in lower maintenance and operating costs.

Holliday Brings Project Management Expertise to GreenWood, Inc.

Written on . Posted in Press Releases.

GreenWood, Inc. announces the addition of David “Doc” Holliday as Special Projects Manager. In this role and as a member of the company’s leadership team, Doc will be working in all aspects of the business operations with both clients and GreenWood associates.

Doc brings more than 30 years of leadership and maintenance/facility operations expertise to this position. Prior to joining GreenWood, Doc held multiple roles at GE with the last 10 years as the Facilities Manager for the Gas Turbine plant in Greenville. At GE, Doc completed leadership development and management coursework at GE University in Crotonville; was Six Sigma Certified; and served on the Board of Directors for the Turbine Federal Credit Union. Before his time at GE, Doc served in the United States Navy.

“Doc is a great addition to our leadership team,” says Brad Wood, President of GreenWood, Inc. “He brings a tremendous amount of maintenance and operations experience that will be applied to the projects he executes both externally and internally. We’re extremely pleased to have Doc on our team and welcome him to this pivotal role within the company.”

SMRP Annual Conference

Written on . Posted in Press Releases.

The Society for Maintenance and Reliability Professionals (SMRP) 25th Annual Conference recently took place in Kansas City, Missouri with over 1,000 maintenance, reliability and physical asset management professionals attending. GreenWood’s Kevin Crittendon represented the company while attending numerous sessions and networking opportunities centered on best practice sharing between members.

A wide range of programs and sessions covered topics on leadership, asset management, planning & scheduling, equipment reliability, materials management, and more. If you are not involved with SMRP, we encourage you to do so. They offer a wealth of resources designed to help you expand your knowledge and skills that improve processes and procedures while building connections with others in the industry. Professional development webinars, education programs, certifications, and a knowledge-rich library deep with resources are available to all members.